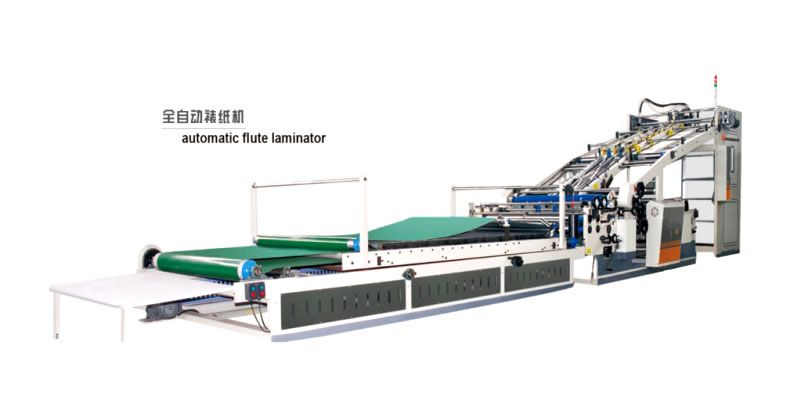

Automatic Lamiantor-S with 1 Feeder for Surface Paper and 1 Feeder for 2 Ply Corrugated Cardboard

This model of laminator is an old model in the carton laminator which we can produce. After laminating, to ensure the printed paper neat to the 2 layer corrugated cardboard is the most important index, it influence the quality of corrugated carton directly.

In this old model, the design of neat part is after laminating, the equipment will push the front part of the carton to make the print paper neat to the corrugated cardboard. It has a little bigger tolerance. So we do not suggest this model machine now. m

Carton laminator can laminating corrugated carton, also can laminating solid cardboard.

As we know, the carton factories buy lamiantor because it can laminting offset printed paper on the 2 layer corrugated cardboard to be a 3 layer corrugated carton, because for corrugated carton, the printing machine is only adopt water ink but no offset printing, then the printing quality can not meet the high printing effect packing request. So laminating an offset printing surface paper on the 2 layer corrugated cardboard is a good solution for this condition. In fact, it is only only can flute surface paper on corrugated cardboard to be a corrugated carton, it also can laminating the offset printing paper on solid cardboard to make boxes. The working principle is same, just feeding material is difference. 1 feeder feeding the printed paper, and the other feeder feeding the solid cardboard to be instead of 2 layer corrugated cardboard.