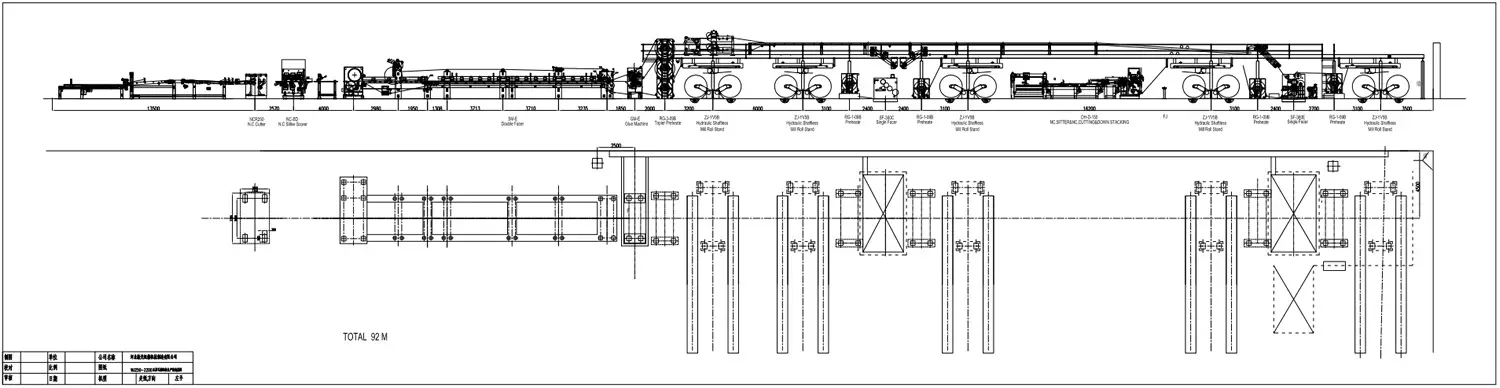

Corrugated Cardboard Production Line

Corrugated cardboard is a kind of low technology and low added value product, the corrugated carton manufacture if want to live and win in the fierce competition, they have to increase their scale and capacity. Since the emergence of the corrugated cardboard, the corrugated machine is developed in line with its trend, by now, the corrugator lines are still in research and develop for meeting the new inquire of the corrugated carton market.

The first single facer is invented in year 1871, and by now, it has been a fully intelligent corrugated cardboard production line with produce management system and conveyor logistic system. Implemented the computer control for material feeding, production, orders arrange, and finished product output of corrugated carton. Let me introduce you each parts of the corrugated paperboard production line.

- Mill roll stand.

It is a holder for paper roll, working with a rail car, workers put the paper roll on the rail car, then it will take the paper roll to the mill roll stand. There are 4 arms in both side of the mill roll stand, each side with 2 arms, they can be moved left to right, also can move toward to middle or separate for clamping the difference size paper roll. The mill roll stand can feeding the papers to single facer.

- Auto splicer

This is an assistant equipment for the mill roll stand, it can save cost for producing, reduce the waste paper for feeding new paper. Normally it is adopted by the corrugated cardboard production line which speed is higher than 150m/minute. It can achieve the function that when a paper roll are finished, we have to change a new paper roll to the mill roll stand, and stop the facer for paper feeding, with auto splicer, the paper can go into the single facer automatically, no need to stop the single facer, and few waste of paper.

- Single facer

The single facer is the earliest machine for making corrugated carton, the first carton machine in the world is a set of single facer in width only 0.5m. so we can know the single facer is the hart of the corrugated carton machines for making corrugated carton. By now, it has lots of types and models, and many of new type are emerging continuously, like the cassette type, it is easy for changing flute, dual flute type, it has two flute type in one single facer. No matter what type of single facer, its function is for making 2 ply corrugated cardboard. One single facer can produce 2 layer corrugated cardboard, then 3 layer corrugated cardboard production line has 1 set of single facer is enough, and 5 layer corrugated paperboard production line need 2 sets of single facer, then we can know, 7 layer corrugated carton production line need 3 sets of single facer.

- Pre heater

Pre heater is also called pre cylinder, heating cylinder. Its main function is for bake the paper, if the paper have too moisture, it can not forming flute, so the pre heater is installed near the mill roll stand, the paper will pass the pre heater firstly and then go to the single facer to produce 2 layer corrugated cardboard. And when the single, double or triple 2 layer corrugated cardboard go to together for combine to 3 layer, 5 layer or 7 layer corrugated cardboard, before go to the gluing machine, the papers and 2 layer of corrugated cardboard will be pass the pre heater again for a strong sticky. So in 5 layer corrugated line, there is one set of 2 layer pre heater, and in 7 layer corrugator line, there is a 3 layer pre heater.

- Conveyor bridge

This is a steel structure bridge with the function of conveyor. Before this machine, it is single facer, the paper is formed to 2 layer corrugated cardboard by single facer, then there is a feeding system for taking the 2 layer corrugated cardboard up to the conveyor bridge. The conveyor bridge also lake a storage, it stores the 2 layer corrugated cardboard, then if any stop of other machines in the corrugated cardboard production line, the it will not influence other working machines. In theory, the higher speed corrugated carton line needs stronger profile steel structure.

- Gluing machine

This machine for making the multi layer corrugated cardboard from the 2 layer corrugated cardboard. The 2 layer corrugated cardboard from conveyor bridge to be in to the multi layer pre heater firstly, after baking, the 2 layer corrugated cardboard and 1 layer of paper go into the gluing machine for gluing on the cardboard and paper, after gluing, they can be sticky together. For example, if we produce 3 layer corrugated cardboard, then1 of 2 layer cardboard paperboard and 1 of paper will come to gluing machine for pasting, if produce 5 layer corrugated cardboard, then it will be 2 of 2 layer corrugated cardboard and 1 of paper come to gluing machine for pasting. Produce 7 layer corrugated cardboard, it will be 3 of 2 layer corrugated cardboard and 1 of paper come to gluing machine to be together.

- Double facer

The double facer is for pressing and combining the multi layer corrugated cardboard. As we mentioned, the 2 layer of corrugated cardboard and paper pass the gluing machine for pasting glue, then after gluing machine, the 2 layer corrugated paperboard and paper will be combined together and sticking by double facer. Double facer have a transfer and heating, pressing function. There are lots of heating plate on the double facer, steam go into the heating plate to heating the multi layer corrugated cardboard, the belt of double facer will press and push the multi layer corrugated cardboard towards to the end of the double facer, in this process, the glue will dry, and the multi layer corrugated cardboard will be combined stronger and move to the next machine.

- NC slitter scorer

The NC slitter Scorer is the first machine of the dry part in the corrugated cardboard production line. As same as its name, we know it has the function of slitting and scorer. When the corrugated cardboard comes here, it has been the finished multi layer corrugated cardboard, but it is still one piece. Slitting means slitting the corrugated cardboard into the size as we need. For example, the whole corrugated cardboard size is width 1800mm, but our finally request size is 600mm width, then the slitter can slit the 1800mm width corrugated cardboard to be 3 pieces of 600mm width corrugated cardboard. And scorer mean that for making carton, we need press indentation on the corrugated cardboard, then it will be simple to fold to be a carton, and the scorer is just for this. After setting the scorer size, it will be finished scorer automatically.

- Cut off machine

The NC slitter scorer for slitting the cardboard in the width we request, then we also need a machine for cut off the corrugated paperboard into the length as we need. Cut off machine is the part with this function in the corrugated cardboard production line. Years ago, it has mechanical type, it can only run in low speed, then as per the higher speed trend of the corrugated cardboard production line, the NC cut off machine was invented, and it adopt straight blade structure, its speed is higher than before, but because straight blade has a bigger shear force, the cutting edge of the corrugated paperboard was with burr. Then the helical blade structure came out and popular, even speed 350m/minute, this structure cut off machine also can meet the quality inquire.

- Stacker

For corrugated cardboard production line, the final process is stacking the corrugated cardboard wish is cut in size as our design. As per difference request, the stacker also has many types. For low speed corrugated carton line, a simple stacker is enough, and for high speed corrugated cardboard line, we need the NC stacker. For the corrugated carton manufacture who produce corrugated cardboard for themself using, after producing corrugated paperboard, they will use it to produce cartons, then small gantry stacker is suit to them. But for the corrugated cardboard manufacture who just produce corrugated paperboard and sale, then large gantry stacker is a good choice for them. We also produce some other stacker like lift stacker, Z stacker, they are all made in order of customers’ difference inquire.

- Production management system for corrugated cardboard production line

For high speed corrugated cardboard production linem, the production management system is necessary. It can arrange difference orders reasonable, monitor the working condition, change orders automatically, no need people to finish it. It can be operated on 1 computer or more computers. Easy for the supervisor of the carton factory to check the producing process of each orders. No need to go to the producing plant, just in office, all data and machine status will be shown and control in the office. This achieves the intelligence of the corrugated paperboard production line.

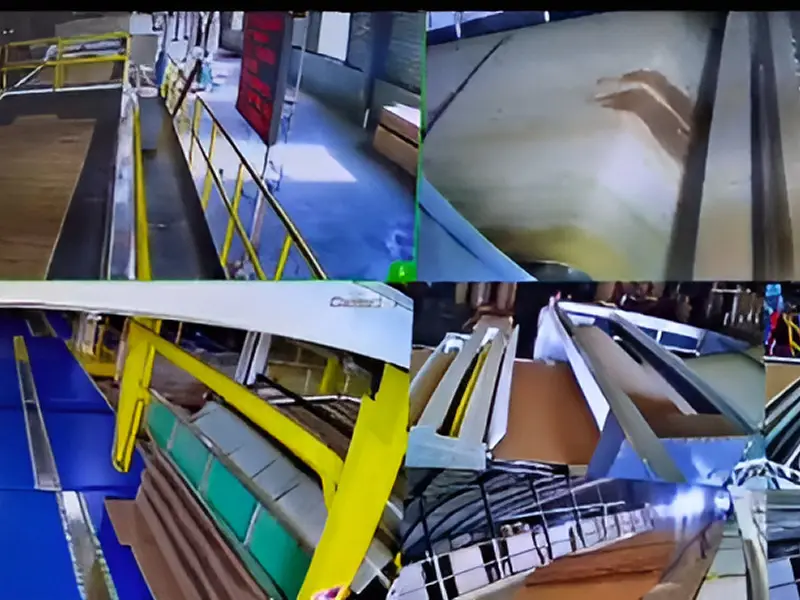

- Conveyor and logistic system

The labour cost is bigger and bigger these years, to reduce the cost, machines to be instead of worker is the industry develop trend. Special for the low technical labor works, machine is a better choice than worker. Like handling work, in the corrugated carton manufacture, take paper roll to the mill roll stand, take finished cartons to the store, all of these jobs need workers. And now we have the conveyor and logistic system to do it. It include two parts, one is material logistic system. It means the machine take the paper roll from the material store to the mill roll stand. The other one is finished product conveyor and logistic system, it means after stacking of corrugated cardboard production line, the pallet of corrugated cardboard will goes to the finished product store automatically.