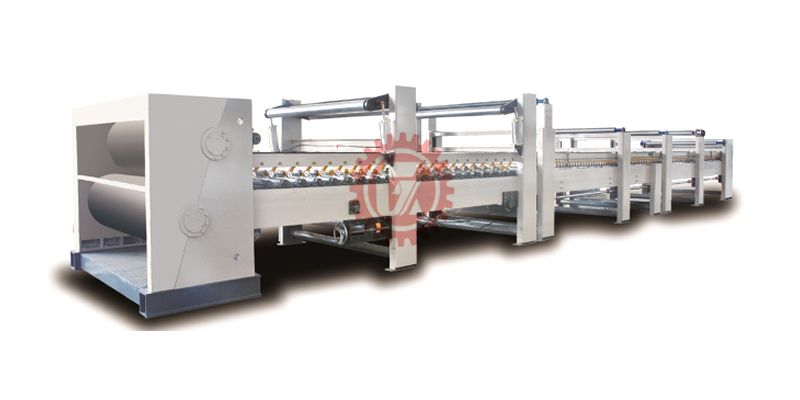

Double Facer

Purpose and characteristics

The double facer is the core carton machine of the corrugated cardboard production line. Its main purpose is to heat, glue and dry the single-layer or multi-layer single face corrugated cardboard coated with adhesive and facial paper to form multi-layer corrugated cardboard and flatten it.

Main structure

Double facer is mainly composed of heating dryer, cooling part, driving part and other parts

- Dryer section

The main function of heating and drying is to gelatinize the starch in the adhesive after heating the single face corrugated cardboard and surface paper coated with adhesive, improve the adhesive force of the adhesive, and make each layer of paperboard closely bond with each other by applying appropriate adhesion force. At the same time, under the heating effect, the moisture in the paperboard is evaporated, so as to form a flat multi-layer corrugated cardboard.

- Cooling section

The main function of the cooling part is to naturally cool and set the corrugated cardboard after bonding and drying under the pressure of the upper and lower cotton belts, so that the formed cardboard surface is flat and the cardboard does not warp.

- Drive part

The main function of the driving part is to drive the upper and lower driving rollers to drive the cotton belt and draw the cardboard to run

The motor power drives the upper and lower drive rollers through the deceleration of the pulley and gear, so as to drive the cotton belt to pull the paperboard.