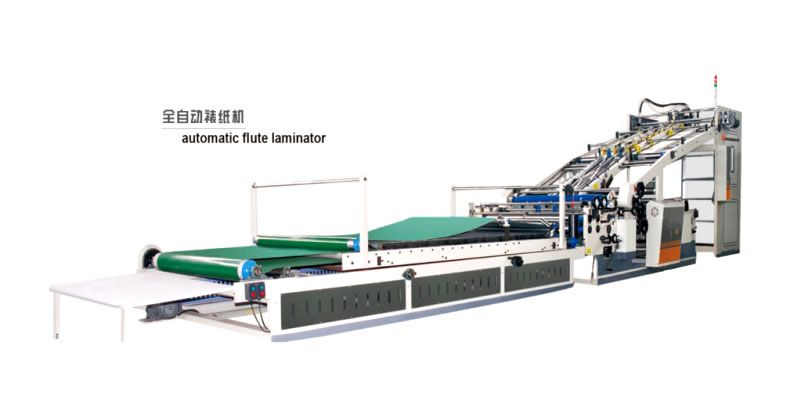

Automatic Lamiantor-S with 1 Feeder for Surface Paper and 1 Feeder for Corrugated Cardboard

- This corrugated carton laminator is an old model, it is pushed neat in the rear part, it is nearly be eliminated

Why do we need the carton laminator?

Many customer who is new in carton industry, they have a same question, what is the carton laminator for? Why do you have this machine? In fact, there are lots of carton factories do not need carton laminator, because they have corrugated cardboard production line to producing corrugated cardboard, also they have flexo printing slotting rotary die-cutting machine to produce cartons. And what is the carton laminator for? It is for the cartons which are requested high quality printing, it means the offset printing corrugated cartons.

By now, I think you know why we need the carton laminator, its function is for laminating an offset printing paper on the 2 layer corrugated cardboard or 4 layer corrugated cardboard. The flexo printing machine can only make flexo printing on the carton, though it has HD flexo printing by ceramic roller and doctor blade, but its quality can not be instead of the offset printing.

So when a carton factory’s main customer is for high price product packing, it has a strict request on printing effect, then we have to consider the carton laminator to produce the cartons.

Laminator working principle.

Normally, the auto laminator with 1 auto feeder for the offset printed paper, and 1 auto feeder for the 2 layer corrugated cardboard. We put dozens of the offset printed paper on the auto feeder, and put dozens of the 2 layer corrugated cardboard on the other feeder, then the 2 auto feeders will feeding the papers and cardboard at same time, the printed paper will be meet the 2 layer corrugated cardboard after pasting, and when they meet each other, they will be laminated and stick. There is an equipment for make the laminating cardboard neat, make sure the printed paper can laminate on the 2 layer corrugated cardboard neatly. And then the laminated cardboard will go into the pressure part, after pressing, the cardboard will be strong.

Application of carton laminator

Most carton factories buy the carton laminator for producing high quality printing corrugated carton, and its main product is 3 layer corrugated cardboard. The offset printed paper is one layer, the 2 layer corrugated cardboard is 2 layer, then after laminating it is the 3 layer corrugated cardboard. Also there are some orders request the 5 layer corrugated carton, how to produce 5 layer corrugated carton by laminator? It is not a problem. The carton making factory can buy 2 sets of auto carton laminator, one set laminator for producing 4 layer corrugated cardboard, we put 2 layer corrugated cardboard on both 2 auto feeder of the laminator, then after laminating, the corrugated cardboard is in 4 layers. Then we put the printed paper and 4 layer corrugated cardboard on the 2 feeders of the other lamiantor, after laminating, it is 5 layer corrugated cartons.

As per this request, we also have a model of laminator special for producing 5 layer corrugated carton, it has 3 auto feeders, 1 feeder is for feeding printed paper, and the other 2 feeder is for feeding 2 layer corrugated cardboard ,after laminating, it is 5 layer corrugated carton directly.