Economic model single facer SF10 suction type traditional design

Read MoreSingle facer is the key corrugated carton machine for producing corrugated paperboard. It is the only machine for forming flute and making 2 ply corrugated cardboard in the corrugated carton production line. Old model single facer only can be with 1 pair of flute roller, that means 1 single facer can only produce 1 type of flute, but now the new cassette model single facer can be with more flute roller, then it can produce more types of flute.

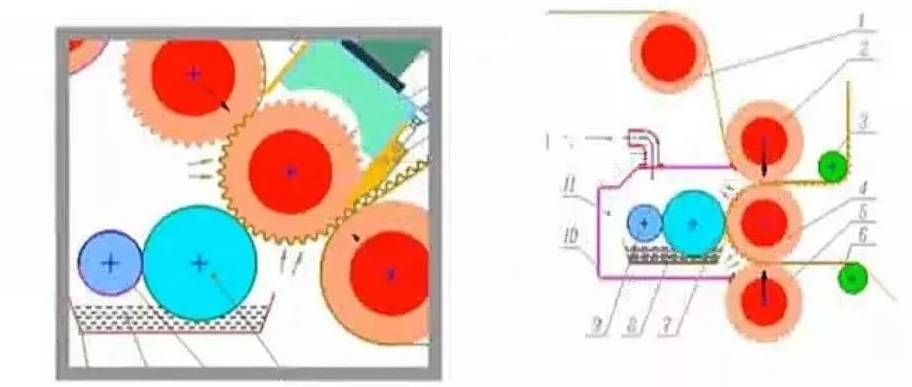

Single facer working principle

The corrugation paper will pass though the gap which is between the 2 pieces of flute rollers to forming the flute shape. And pass the gluing roller to finished glue pasting, then laminating on a surface paper, press and stick by the lower flute roller and pressure roller to be a 2 layer corrugated cardboard, finally it will output from the single facer and transfer to the conveyor bridge by the belt to go to the double facer. This is the whole process of the single facer working in the corrugated carton line.

What is suction type of single facer

All single facer with a pressure to fix the corrugation paper , because when the corrugation paper goes into the flute roller, the flute roller is running in a high speed with a centrifugal force, it will set aside the corrugation paper, it can not form the flute shape. Then how to make the corrugation paper adhere on the flute roller firmly, there are two design. One is negative pressure type, it is suction the corrugation paper by the negative pressure. The other type is positive pressure type, it is suction the corrugation paper by blowing outside of the flute roller.

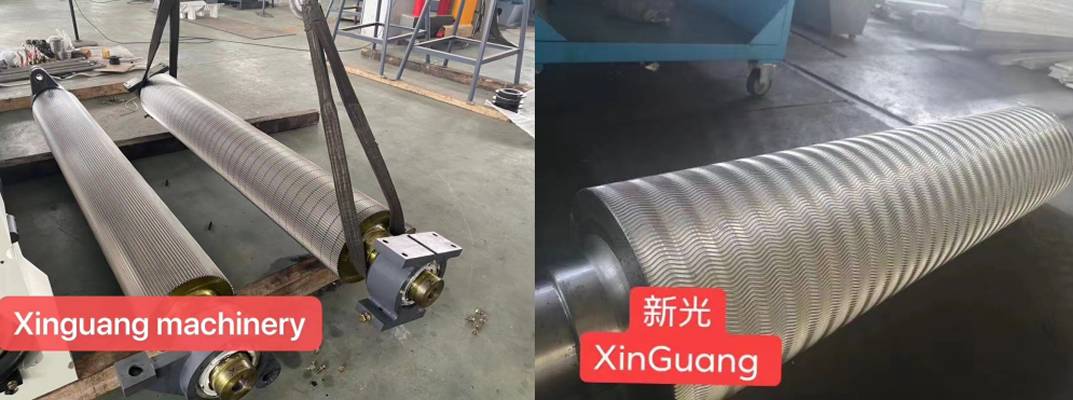

Flute roller introduction

As we say the single facer is the key of complete corrugated carton production line, and the flute roller is the key of the single facer. Because it is with teeth, running in high speed and the two pieces flute roller need to work together, so we have a strict request on the material for producing the flute roller.

Before, we adopt 48CrMo high quality alloy steel, it is with high hardness and working life is 80000 running meter. Now, because the machine speed is higher, for long term working life, most of single facer adopt tungsten carbide flute roller, its working life can be 3000000 running meter. Though its price is much higher than the 48CrMo material. But it is occupying the whole market now.

Flute type introduction

There are lots of flute types in the market, it can be mainly classified in A,C,B,D,E,F,G Big size flute is A flute and C flute, small size flute is B flute and D flute, micro size flute is D flute and F flute, and the smallest flute type is G flute. Big size flute is a little better on working life, because it has bigger teeth height, but if long time no change flute roller, it will be also a problem, because the teeth height can not be meet the request

If small size, special the micro size flute type, it has to be tungsten carbide flute roller, or it will be easy to grinding flat. When we produce 5 ply and 7 ply corrugated cardboard, the flute can be any combination. And now, there are also some special shape flute, like wave flute and Z flute, just if customer need, we can produce the flute type as per customers’ inquire.