Flexo Printing Slotting Rotary Die-cutting Machine

Combination of flexo printing machine

The flexo printing slotting die-cutting machine is the machine for making cartons from corrugated cardboard, by its name, we can know what units does this machine have. We introduce them one by one.

The function of corrugated cardboard auto feeding. This function is act by the lead edge feeder. Worker put dozens of corrugated cardboard on the feeder, then it can feeding the corrugated cardboard piece by piece, and take the cardboard to its next unit, printing unit.

The function of printing, this function is finished by its printing unit. Each printing unit can be in one color. So we can know that, if we need 2 colors, then we need 2 printing unit, and normally, for flexo printing, 4 colors is enough. Some clients get one more printing unit, it for varnish on the carton, then the carton looks like a film layer on the carton surface, but in fact, it is varnish oil

The function of slotting. Most cartons’ shape are same, we call these cartons are ordinary cartons. the slotting unit is for cutting corrugated cardboard in this shape. The slotting unit is also called slotter. It is composed by 4 slotting wheels, on the wheel, there are blade for cutting. When we need difference size cartons, just adjust the wheel distance and phased the blades on the wheel, then it can finished its job.

The function of die-cutting. There are also lots of cartons in difference shape, most of these carton box is for gifts and souvenir packing. The slotter can not cut other shapes of carton, so we have a rotary die-cutter. We can fix the mould on the die-cutter roller, then when the corrugated cardboard pass the rollers, it can be cut by the mould, and the mould is made according to our carton design. Then we can get difference shape cartons by this unit.

Finally is the stacker. Stacker is put behind of rotary die-cutter, after the cartons output from the die-cutter, it will go to the stacker and stacking automatically. Some times, we equip the vibrator equipment on the stacker, it can shake the cartons to peel the scraps which after cutting but still hang on the cartons. And below it is a transfer unit, to take the scrap together for collecting.

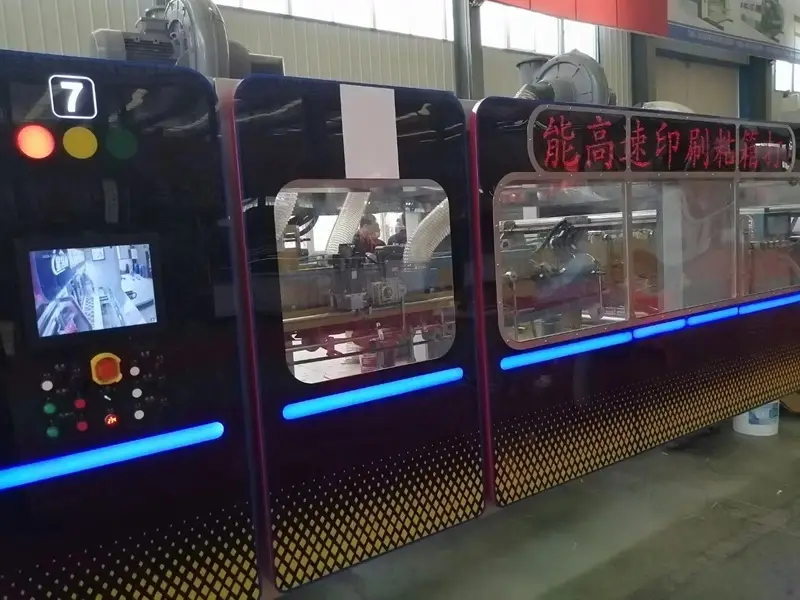

- New type high speed flexo printer slotter die-cutter

Base on above units, the flexo printing slotting die-cutting machine can make good quality cartons, but its maximum speed is around 220 pieces/minute. Because the cardboard is transferred in the machine by belt and rollers. Now we have a new type of transfer system, it is full vacuum suction transfer system. Its speed can reach to 350 pieces/minute. The problem again, transfer speed is no problem, but the ink can not be dried in few seconds. Then we equip the IR heating unit on the machine. Normally there are 2 IR heater on one machine. One is installed behind the printing units, the other one is installed behind the varnish units. Then the ink problem is solved too, and the full set of printing slotting die-cutting machine speed can reach to 350 piece/minmute.

- HD printing of flexo printing

Now, most client prefer HD printing, for flexo printing, the market also has inquire of high quality, high definition printing effect. The old technical is steel anilox printer, its is only 180-280 mesh, it can not make a good effect printing. So we adopt ceramic anilox roller to be instead of the steel anilox roller, the ceramic anilox roller can reach to 300-700 mesh. When the printing effect request more than 350 mesh, we will add doctor blade on the machine, then it can get HD printing effect. Though it can not as same as offset printing, but for a outer packing carton, it is good enough.

- Operation of the flexo printer slotter rotary die-cutter

The operation of the carton printing machine is also significant progress than before. The old machines was operate manually. Workers need to put corrugated cardboard on the feeder one by one, and phase the printing unit, slotting unit and die-cutting unit manually. Even the distance of slotting wheel is also need a worker take rule to measure and adjust one by one, it took long time to adjust machine before producing. Just when changing orders, it will adjust one time, so complex process.

Now, it is so simple and intelligence. Work just put dozens oi corrugated cardboard on the auto feeder, then input datas on the touching screen, then nothing need to do, we can go to the stacker to wait for the cartons which is stacked well.

- Classification and main parameters of carton printing machines

flexo printing machine: maximum carton feeding size, printing size, printing tolerance, colour quantity, speed.

Flexo Printing slotting machine: maximum carton feeding size, maximum printing area, carton skip feeding size, printing plate thickness, color quantity , minimum slotting spacing, maximum slotting length, maximum mechanical speed, paperboard thickness

Flexo printing rotary die-cutting machine: maximum speed, carton size, printing size, minimum slotting gap, maximum slot depth, maximum paperboard thickness, standard printing plate thickness, color quantity and rotary die-cutting size.