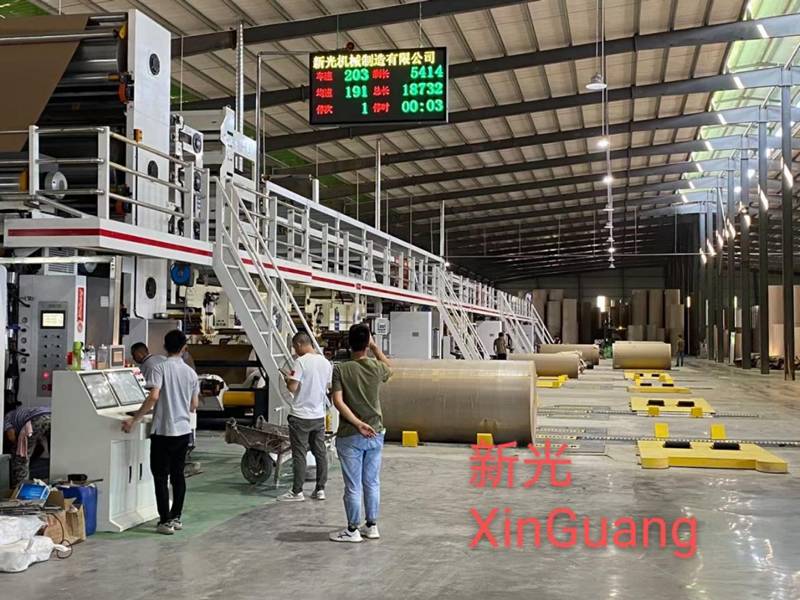

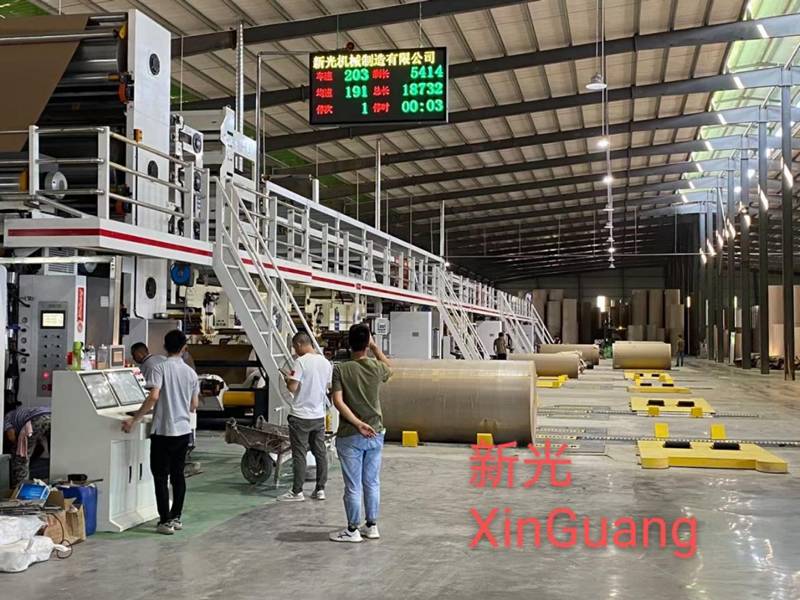

Corrugatd cardboard production line in big width and fast speed

Making corrugated cardboard from paper roll

- 2 layer, 3 layer, 5 layer, 7 layer

- Width: 1400-3100mm

- Speed:100m-350m/minute

- Flute: A/C/B/E/F/G

Corrugatd cardboard production line in big width and fast speed

Making corrugated cardboard from paper roll

Flexo printing slotting die-cutting carton machine perfect effect of printing

Making carton box from corrugated cardboard

Introduction

Carton machine means the machines for making cartons, it has many types of carton machines in difference functions.

The corrugated cardboard production line is the carton pre-processing machine, its function is producing corrugated cardboard from paper rolls.

It can be classified by corrugated cardboard structure as below

| Production line | 7 layer corrugator line | 5 layer corrugator line | 3 layer corrugastor line | 2 layer corrugator line | ||

|---|---|---|---|---|---|---|

| corrugated cardboard | 3/5/7 layer | 5/7 layer | 3 layer | 2 layer | ||

| 7 layer/5 layer/3 layer production line also can be produce 2 layer corrugated cardboard after adding a 2 layer corrugated cardboard slitting and cutting machine.then they can be like below | ||||||

| Procution | 7 layer+2layer corrugated line | 5 layer+2layer corrugated line | 3 layer+2layer corrugated line | |||

| Corrugated paperboard | 2/3/5/7 layer | 2/3/5/layer | 2/3layer | |||

The corrugated cardboard production line is developing all the times, the steel mechanical parts are stronger an stronger, for example, the profile steel size is bigger and stronger than before, heavy type structure can meet higher speed. And about the casting iron parts, we also make it thicker and thicker in years. So now the corrugated cardboard production line is much heavier than the machine years ago.

Beside the machine structure and mechanical parts, The electric parts of the production line have a big change. Early years, the most corrugated cardboard production line adopt Chinese brand, like CHNT, DELTA, and now the corrugated carton production line is is higher speed and bigger size, most production line adopt imported brand electric parts, like OMRON, Siemens. Good quality electric parts has a long working life to save producing cost for the carton manufactures.

After we getting the corrugated cardboard, the next step is to produce carton boxes, and what machine do we need?

The flexo printing slotting die-cutting machine is just what we need. The flexo printing slotting die-cutting machine can making the corrugated cardboard to completed carton which is printed, cutted. Normally it has 1-6 colors for option, and now the varnish on the carton is popular, it looks light and shine after vanish. And now the ceramic anilox roller is more popular to be instead of steel anilox roller, because we have a higher request on the printing quality.

As per the design of the carton, firstly we have to choose how many colors we need for printing. After that, we should consider the how to cut and crease the carton, by slotter or by rotary die-cutter. Then we can test producing, if no problem, we can produce in batch. The waste clean system is necessary for the flexo printing die-cutting machine, because after cutting, there a lots of carton scraps.

We also have some other machines, for folding gluing the carton, then it can be folded and sticky automatically. And some machine for waste paper scrap baling, a carton manufacture has to consider what machine you need as per your factory scale. How many cartons you want to produce in 1 year, what is the size of your workshop, how much of your budget of build the carton manufacture.