Automatic Lamiantor-S5 Can Laminating 5 Layer Corrugated Cardboard Directly

This is the special model of carton laminating machine. It is difference to other all models, because it can laminating 5 layer corrugated carton directly. How to achieve this function?

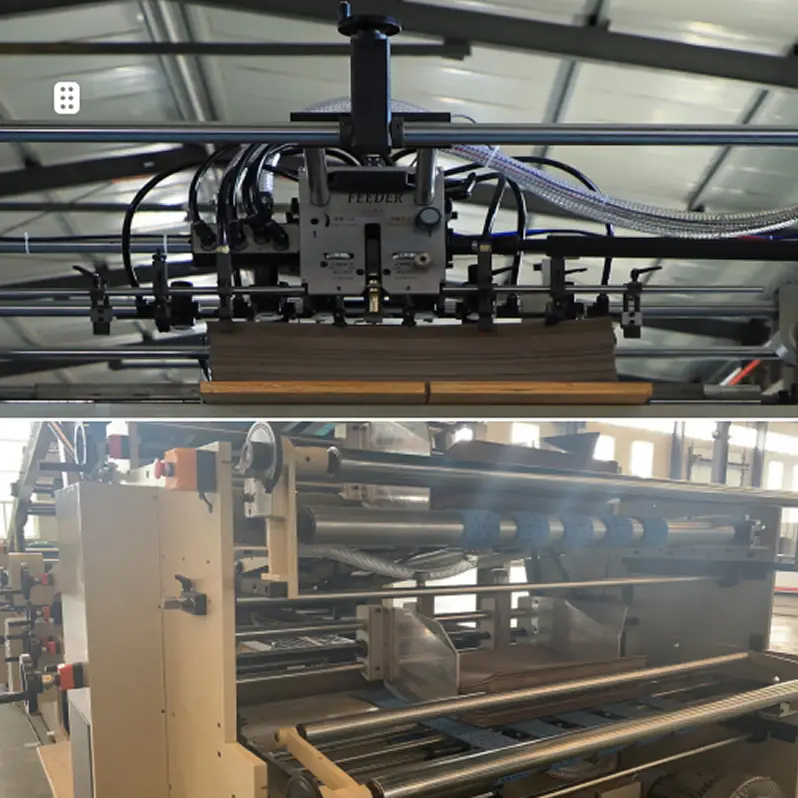

Working principle of this corrugated carton laminating machine

On this machine, it has big difference structure design to other all models. It has 3 auto feeders, normally, the laminator only have 2 auto feeders, 1 auto feeder is for feeding printed surface paper, and the other auto feeder is for feeding the 2 layer corrugated cardboard, then after delivery and gluing, they are laminated to be 3 layer corrugated paperboard.

But this machine has 3 auto feeder, as same as other laminator, the first auto feeder is for feeding printed surface paper, the second is for feeding 2 layer corrugated cardboard, and the third auto feeder is also for feeding 2 layer corrugated cardboard.

After feeding units, the printed surface paper and 2 of 2 layer corrugated paperboard will go to the delivery unit to the gluing units, sure this machine has 1 more gluing unit than the other model of laminator. Other models only have 1 gluing unit, but this machine has 2 gluing units. after gluing, they can be laminated, there are 1 more laminating unit than other laminator t0o, this machine has 2 laminating units, firstly laminating for 3 layer corrugated cardboard, then laminating for 5 layer corrugated cardboard. After that, the 5 layer corrugated cardboard go into the pressure unit. Then the colorful printed 5 layer corrugated cardboard production is completed.

It is so convenient for the customers who want to produce 5 layer colorful printed corrugated cardboard. They do not need to buy 2 sets of carton laminating machine, or process two times on one carton laminator, just this one machine one process is OK.