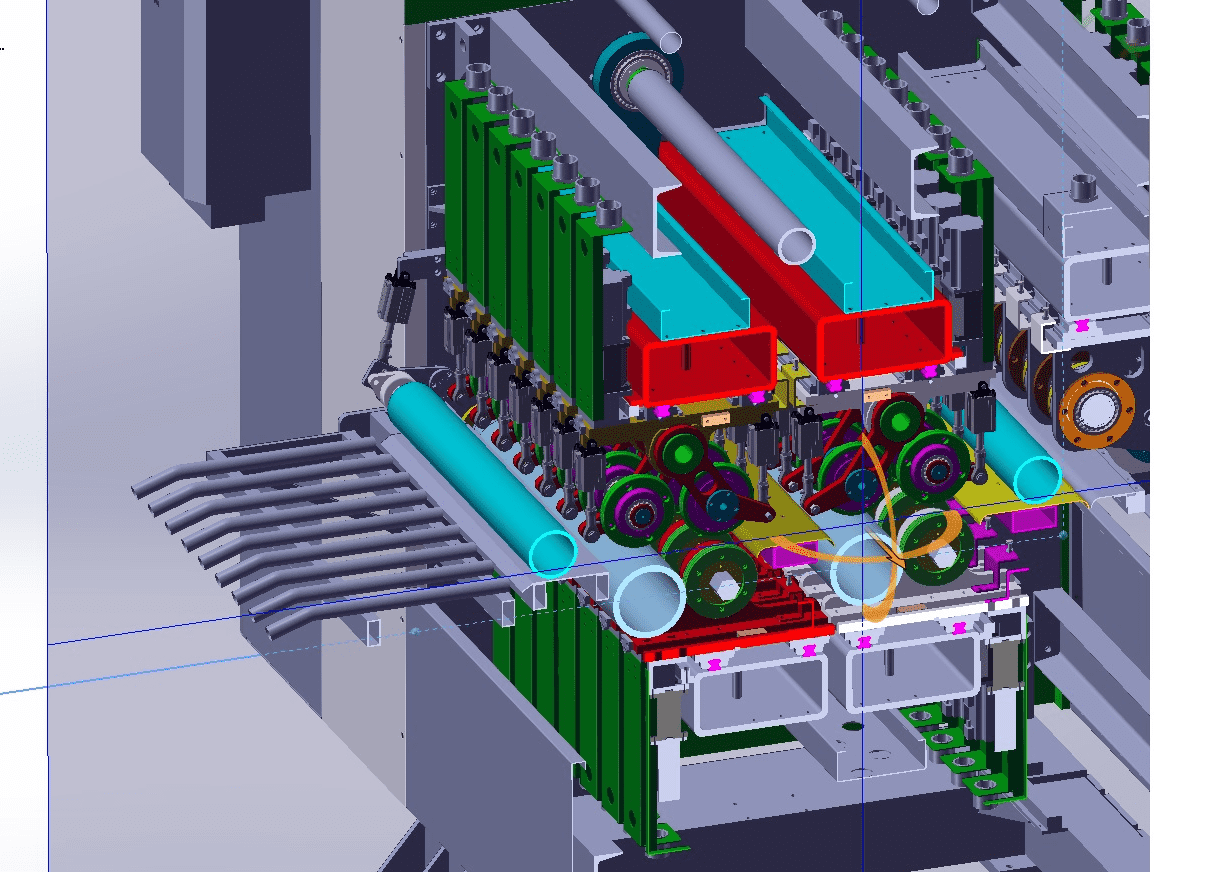

FY-D Slitter Scorer

Technical parameters:

| Working width |

1800-2800mm |

| Design speed |

300m/min |

| Economic speed |

180-300m/min |

| Mechanical configuration |

7 Knife 12 lines |

| Min cutting width |

140mm |

| Minimum indentation distance |

0mm |

| Cutter wheel positioning accuracy |

±0.5mm |

| Horizontal movement of the whole machine |

±100mm |

Structural feature:

- The synchronous servo motor controls the row of knives and wires. Automatic reset. Precise size. Change order time is1-3seconds.

- PLC control system, using CANopen bus system, with order management function, equipped with a synchronous signal input interface with dryer speed.

- HMI with 10.4-inch color touch screen, storage 999 orders, change orders automatically or manually for a single, fault alarm.

- Three kinds of pressure line forms:Convex against the concave(three layers line)、Convex against the concave(five layers line)、Convex against Flat,Three kinds of electric pressure line forms can be converted.Crimping round shades by computer control,linear, and easy to bend.

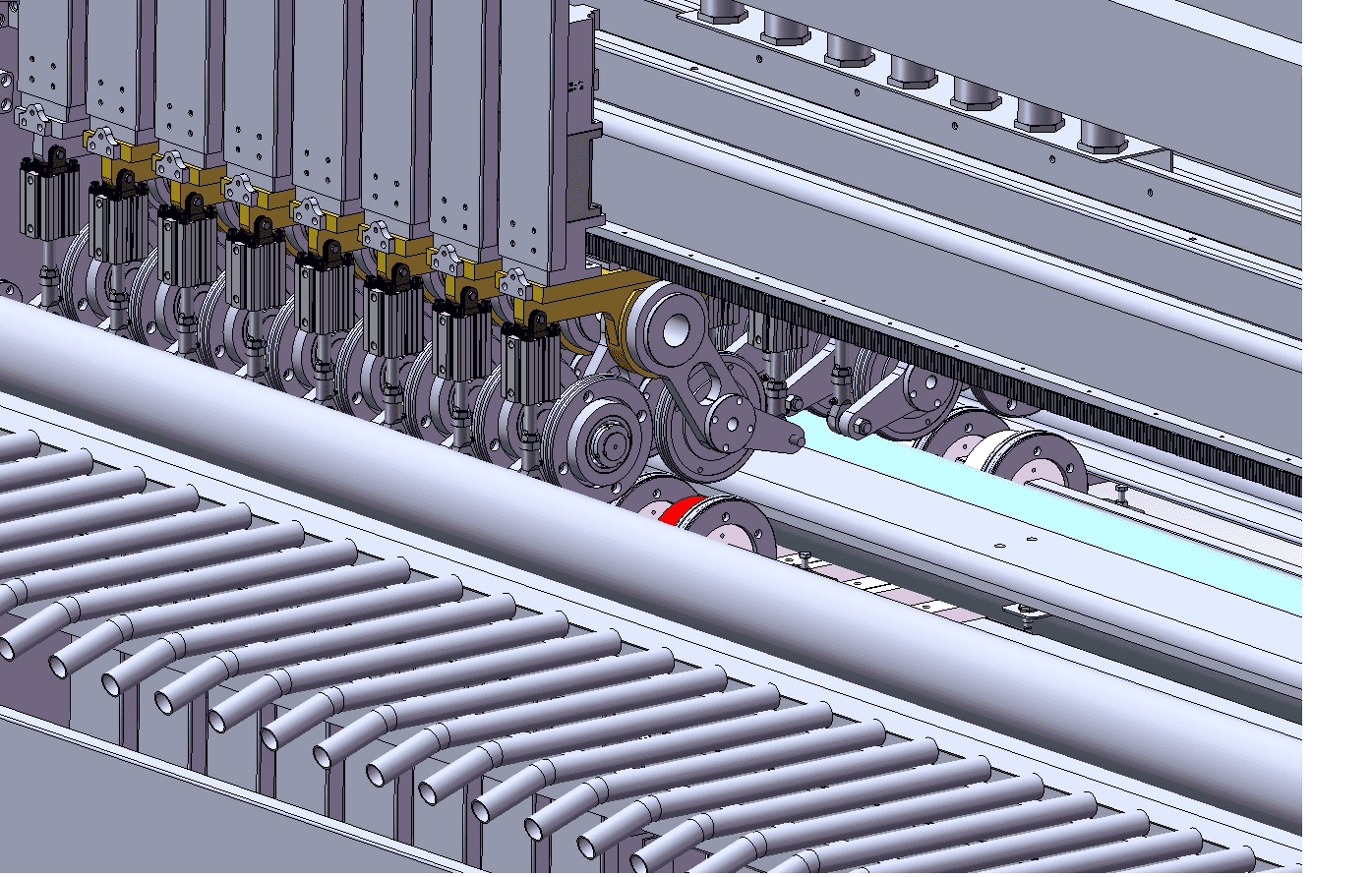

- Using thin tungsten alloy steel knife,sharp blade,long life of more than 8 million meters.

- knife sharpener for computer control,automatic or manual knife sharpener,Cutting edge sharpening can be divided,improve productivity Efficiency.

- Imported synchronous belt transmission is adopted, and the thin blade holder and the crimping seat are supported by linear bearings, and the positioning size is accurate without accumulating errors.

- The cutting and crimping are driven by independent frequency conversion motors. The suction port is automatically positioned with the change order.

- With gas storage tank and low pressure protection function.

Main dynamic parameters:

| Name |

Power |

Voltage |

Frequency |

| Row of single-pole servo motors |

0.75KW |

380V |

50HZ |

| Slitting inverter motor |

7.5KW |

380V |

50HZ |

| Pressure line frequency conversion motor |

7.5KW |

380V |

50HZ |

| Suction outlet frequency conversion motor |

0.55KW |

380v |

50HZ |

Main parts brand and origin:

| Serial number |

Name of main parts |

Brands or place of origin |

Remarks |

| 01 |

Frame |

ShanDong JiNan |

Q345 |

| 02 |

Rail beam |

TianJin |

Q345 |

| 03 |

PLC Programming controller |

Schneider |

CANopen Bus system |

| 04 |

HMI |

Kinco |

10.4 inch |

| 05 |

Row knife servo control |

Huichuan |

750w |

| 06 |

Row line servo control |

Huichuan |

750w |

| 07 |

Proximity switch, photoelectric switch |

Japan omron |

|

| 08 |

Relay |

Schneider |

|

| 09 |

Main frequency conversion motor |

HeBei |

5.5KW×2 |

| 10 |

Horizontal motor |

Shandong Jinzhan Reducer |

|

| 11 |

Suction exhaust motor |

ZheJiang |

0.55kw |

| 12 |

Solenoid valve, cylinder |

AirTac |

|

| 13 |

Bearing |

HRB or C&U |

|

| 14 |

Bearing with seat |

ZheJiang Wuhuan |

|

| 15 |

Tungsten alloy blade |

Sichuan Boyan |

¢260mm |

| 16 |

Linear Guides |

TaiWan |

ShangYin |