Triple Layer Pre Heater is installed before gluing machine

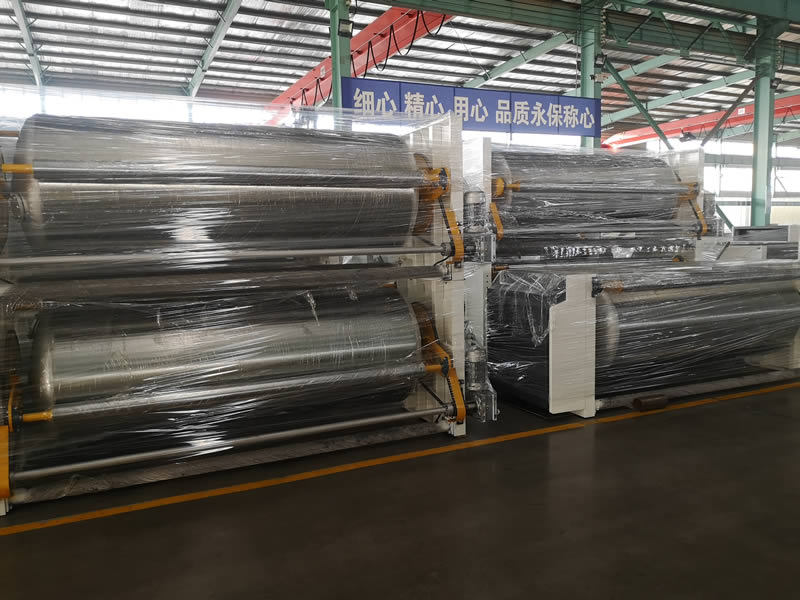

Structure of Triple layer pre heater

The triple layer pre heater has 3 layers, each layer with 1 preheating cylinder. Normally the cylinder have difference diameter to match difference speed production line. We have cylinder in diameter 400mm, 600mm, 900mm, 1010mm, etc. Bigger diameter cylinder match to higher speed production line. The cylinder is made by steel, The surface of cylinder is chrome plate treatment, it is smooth to make sure the paper no broken when it passes on the cylinder. Normally it is packing with some Thermal insulation material, its main function is for heating on the paper and make the paper dry, then make it to be more strong and durable.

The pre heater including its main frame, wave arms, preheating cylinder, wave roller, synchronizing shaft, small chain wheel, drive motor, big chain wheel, fixed roller, strain chain wheel, cover of machine frame, chain. The cylinder is fixed on the main frame.

The preheating cylinder is a type of pressure vessel

As per the standard making organization says, pressure vessel means that the vessel which is with in inner pressure bigger than 0.1Mp, then it is pressure vessel. In the preheating cylinder, inside of the cylinder, we will put water or steam in it, it is a high temperature and high pressure environment, then the preheating cylinder is a pressure vessel. Then after the cylinder production, we have to get relevant certificate of pressure vessel to guarantee its safety.

Triple pre heater is special for 5 layer corrugated production line

As we know, the 3 layer production line equipped with 2 layer pre heater, then 5 layer corrugated cardboard production line with equip 3 layer pre heater. Because the 5 layer corrugated cardboard production line has the conveyor bridge in 2 layers, then there are 2 of single face corrugated cardboard come out from the conveyor bridge, then No. 1 layer cylinder for heating 1 single face cardboard, No. 2 layer cylinder for heating the other 1 single face cardboard, and the No. 3 layer cylinder for heating the draft paper.

After the triple pre heater, the 2 of single face corrugated cardboard and 1 of paper will go in the gluing machine for gluing, then they go into the double facer for heating and bonding.